Sizes & Surface

| Size |

Surface |

| 3050*1120*18 mm |

Polished (Glossy), Leather, Honed (Matte finish) |

| Custom sizes are possible |

Polished (Glossy), Leather, Honed (Matte finish) |

Trade Terms

| Port |

ICD Sanathnagar (HYDERABAD) (INSNF) |

| Shipment Terms |

FOB, CFR, CIF, EXW |

| Payment |

ADVANCE, L/C, D/P,D/A |

Basic Parameters

| Absorption by weight |

App. Density KG/M3 (Cube) |

Abrasion resistance |

Modulus of rupture |

Flexural strength |

Compress strength |

Mohs' hardness |

Specular gloss |

| 0.06% |

>2100 |

34 |

55 - 65 |

40 - 60 |

150 - 250 |

6.0 - 7.0 |

55 – 70 |

Why Choose Quartz Countertops

- Zero Porosity - Practically zero porosity, preventing the absorption of water or other liquid

- Durable - High hardness and resistance to abrasion and scratching.

- Acid Resistant - Resistant to fats, oils and acids from foods: lemon, tomato, wine, etc.

- Great flexural strength and impact resistance.

- Easy to clean - Easy to clean and maintain.

- Antibacterial - Quartz does not need antibacterial chemicals, since the absence of pores prevents bacteria acting as a natural bacteriostatic. Hence it is food safe, and used widely in kitchens

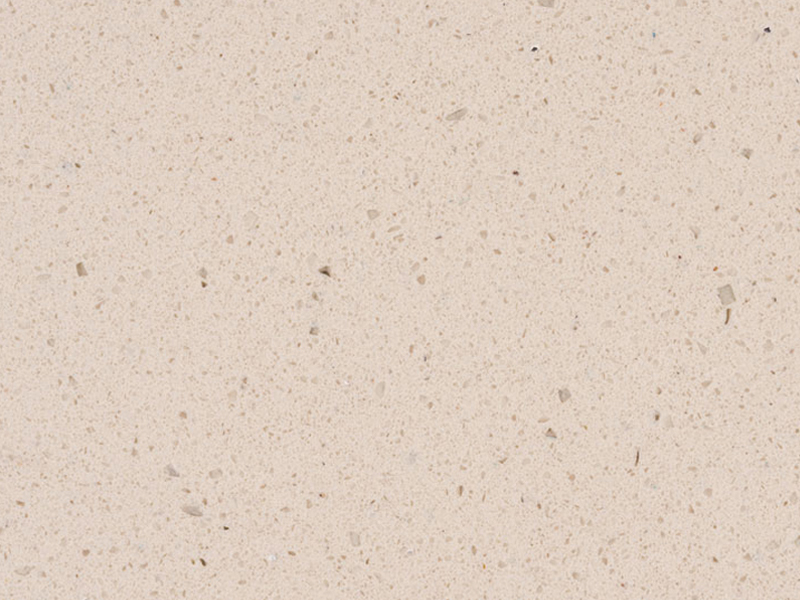

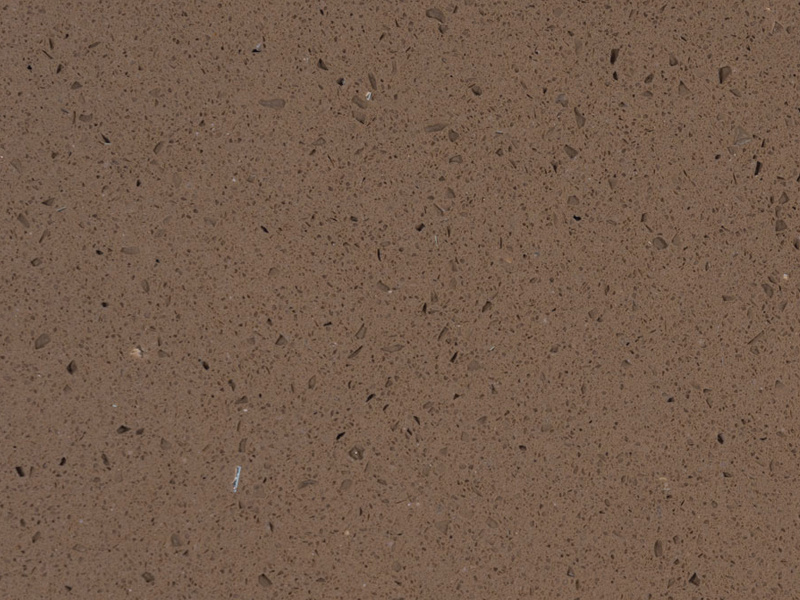

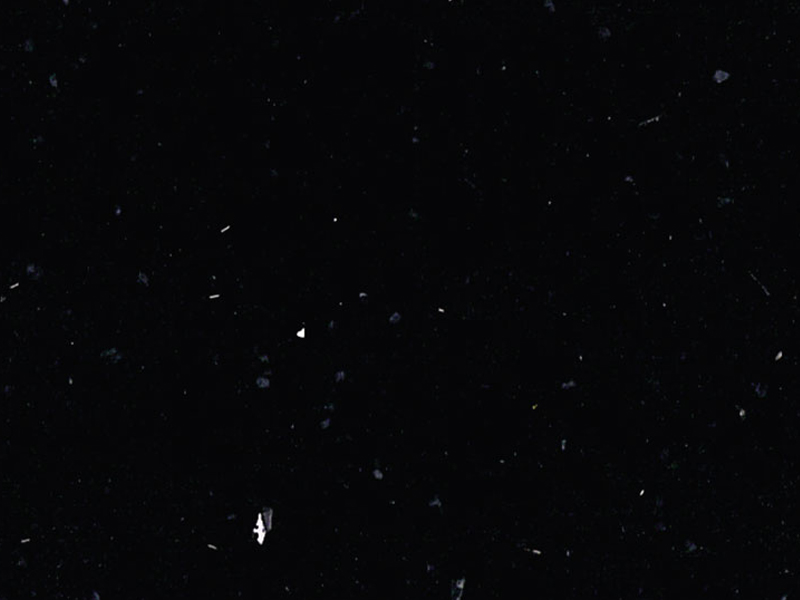

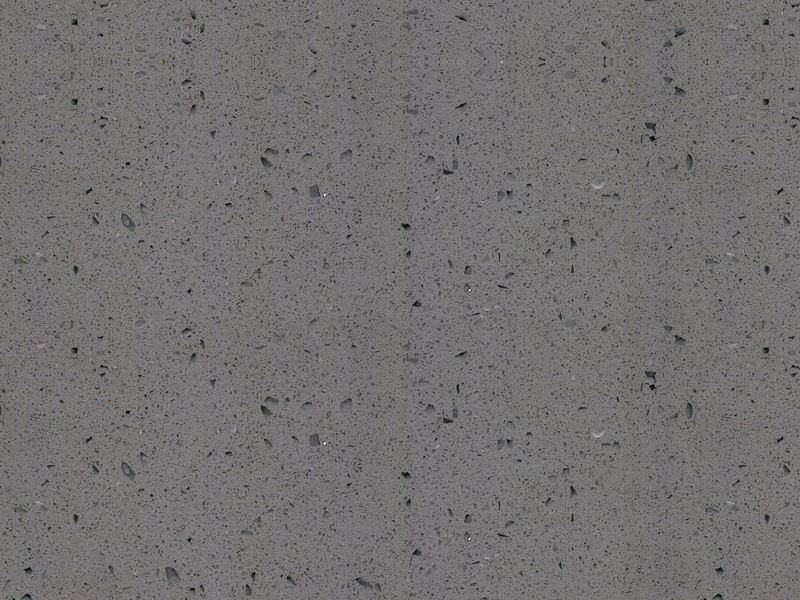

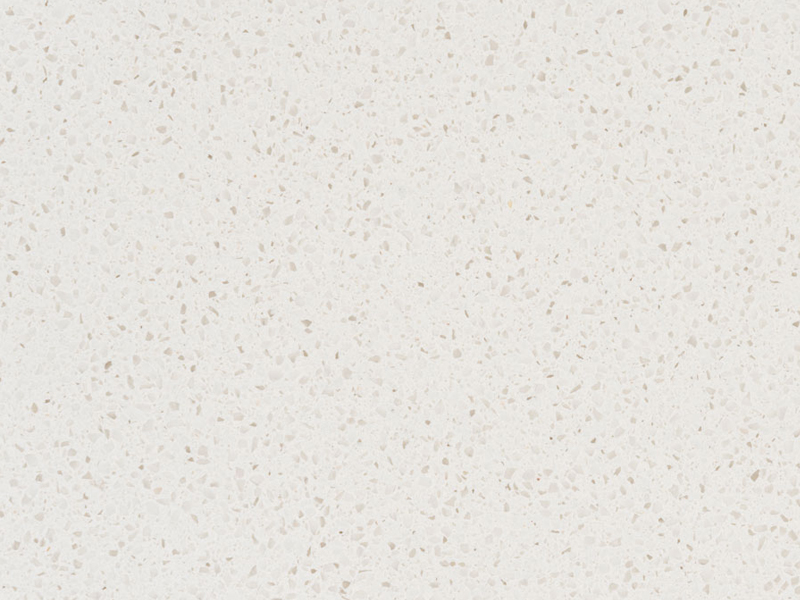

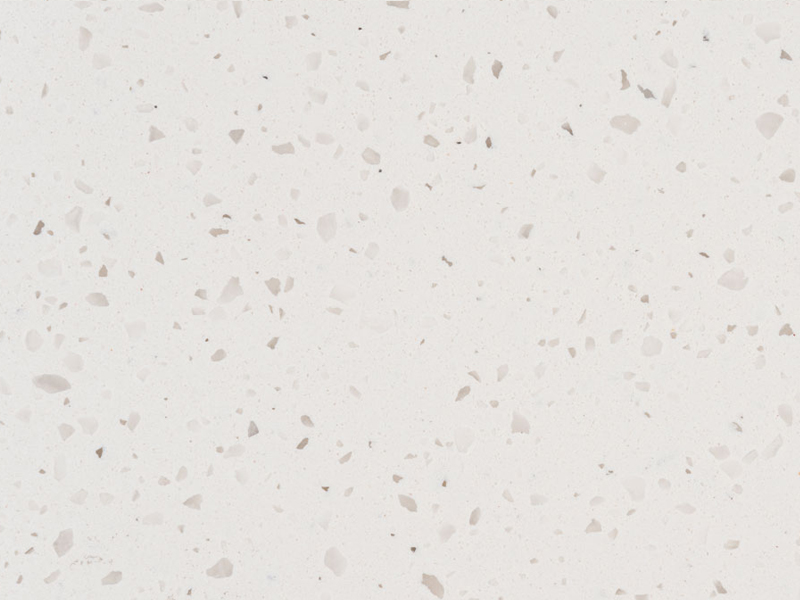

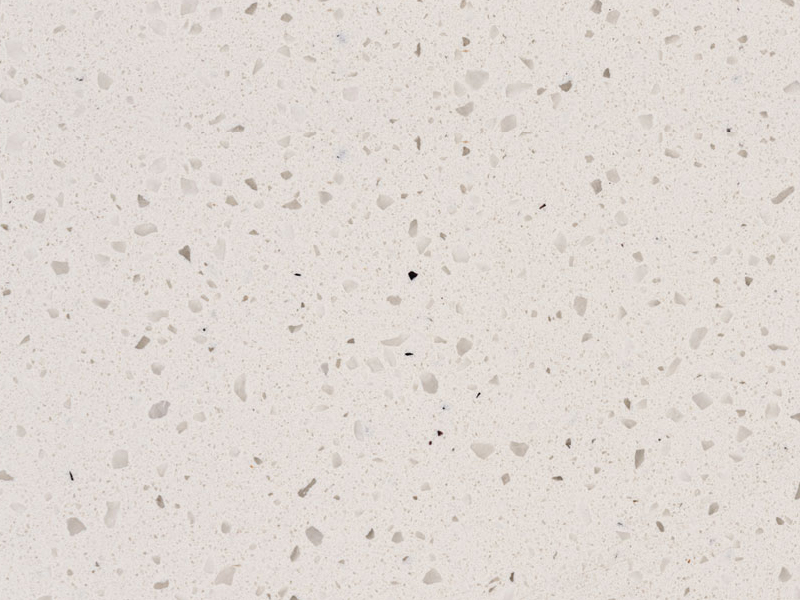

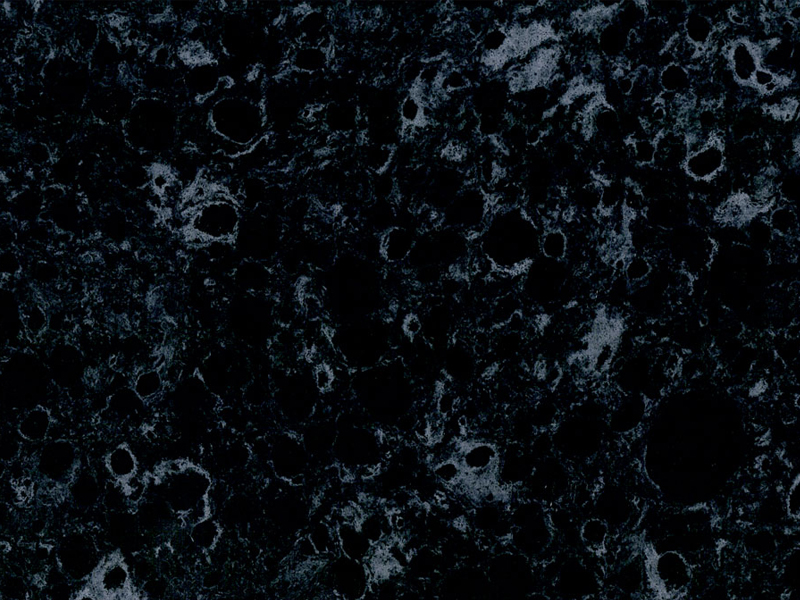

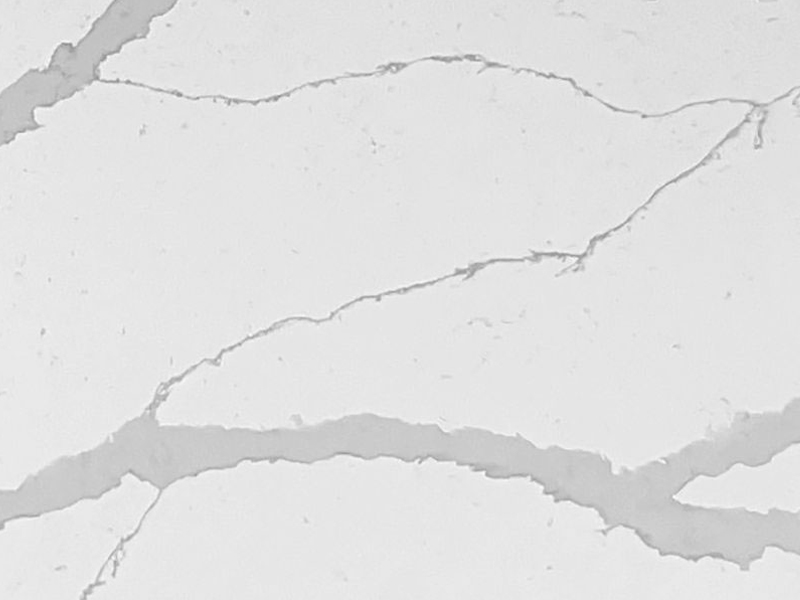

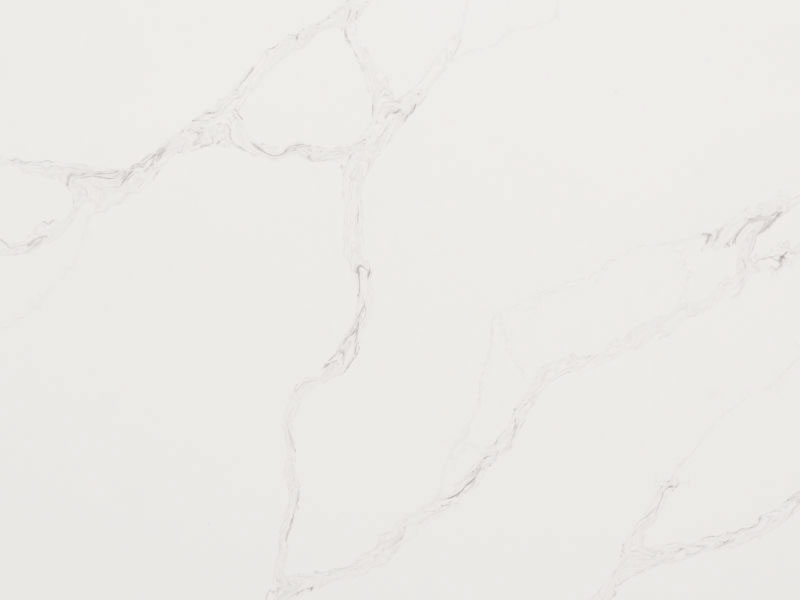

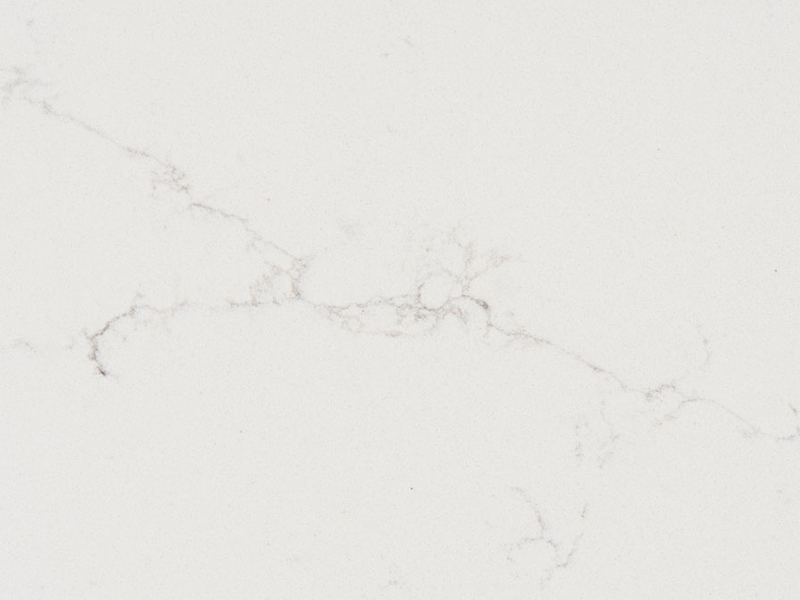

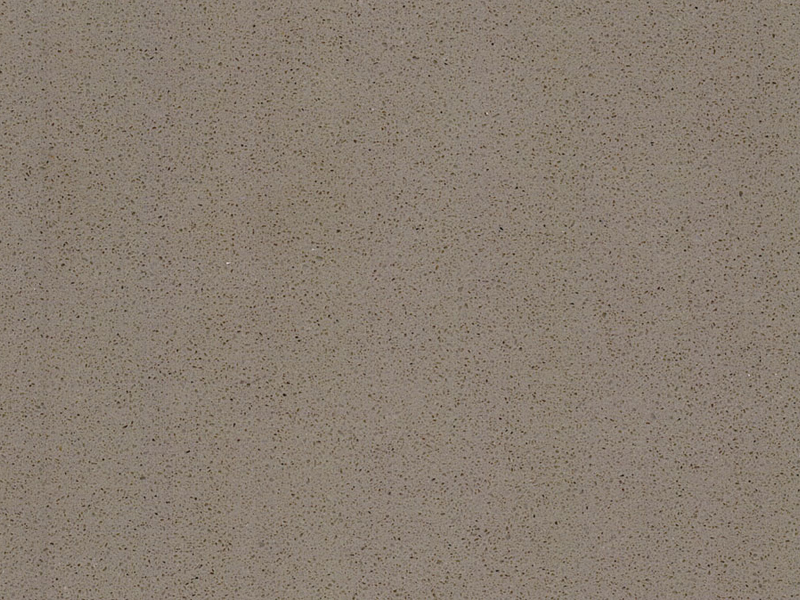

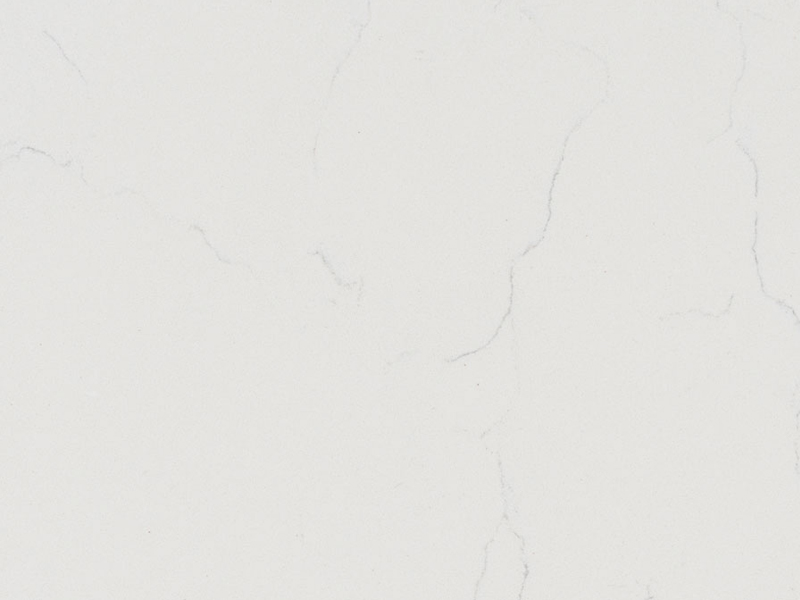

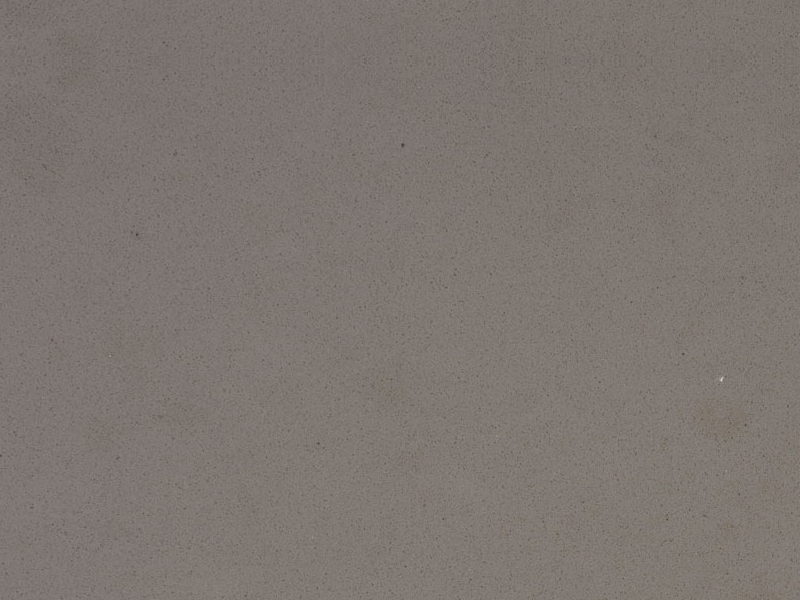

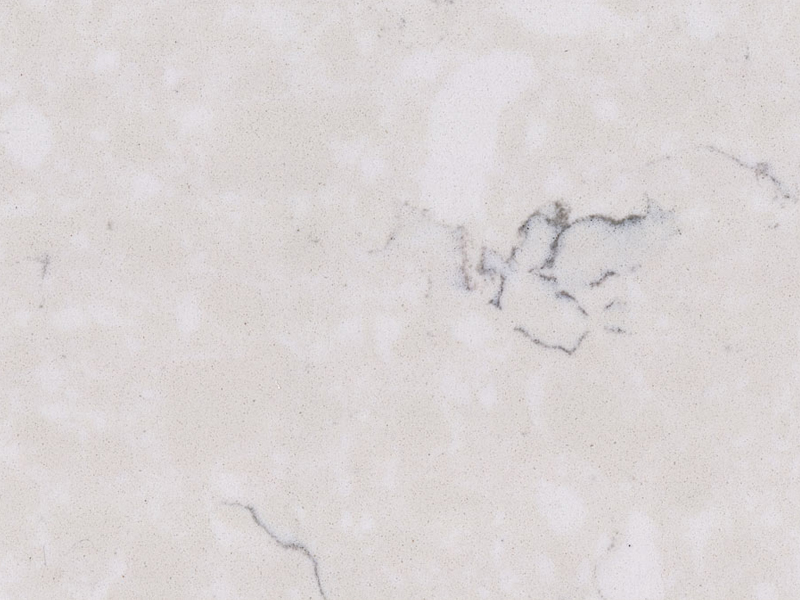

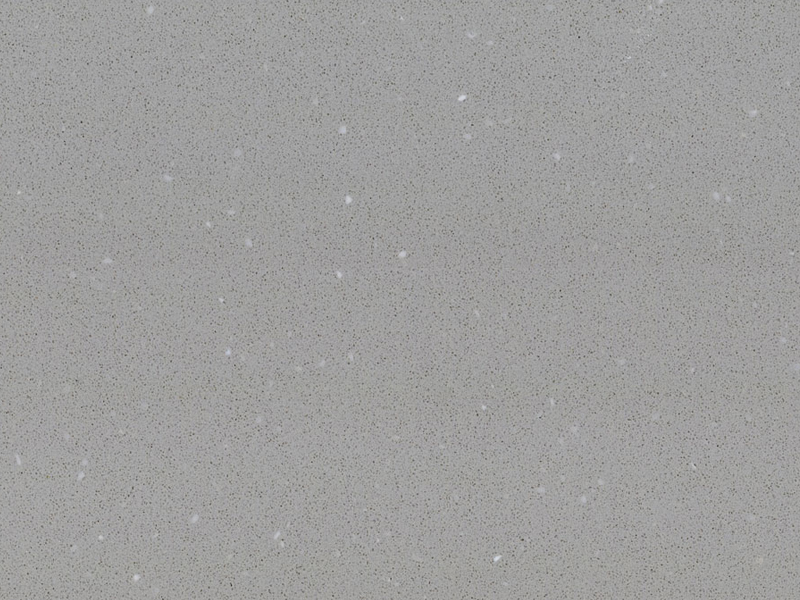

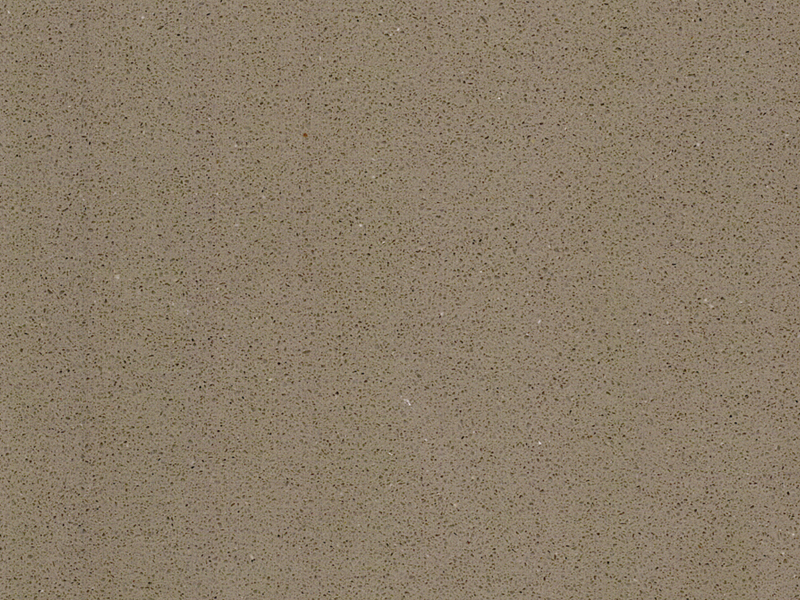

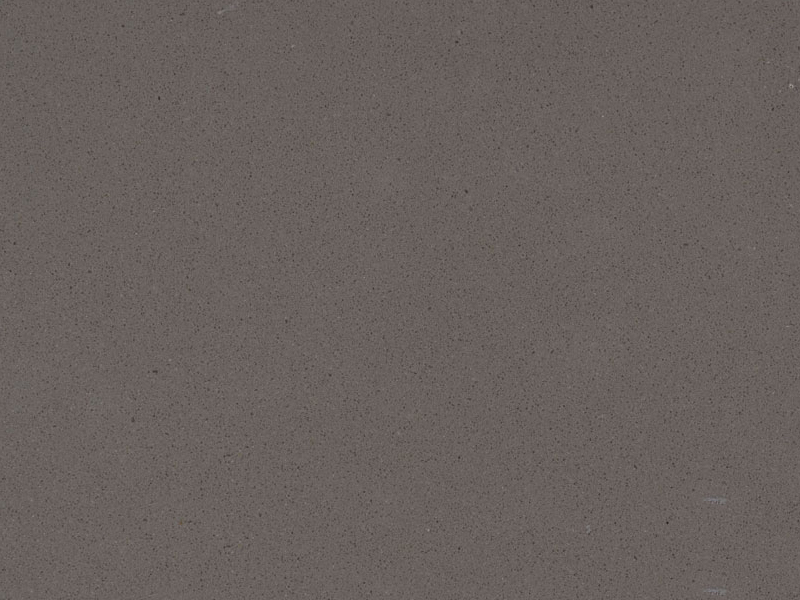

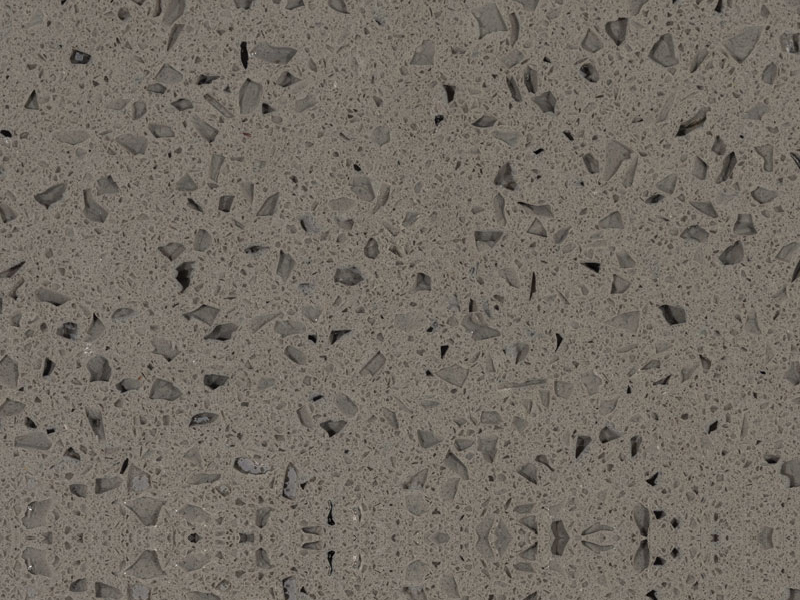

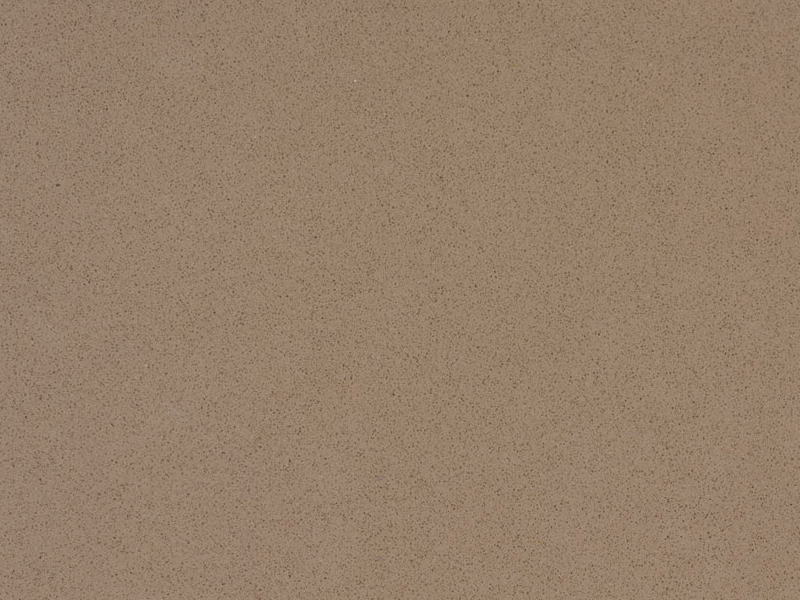

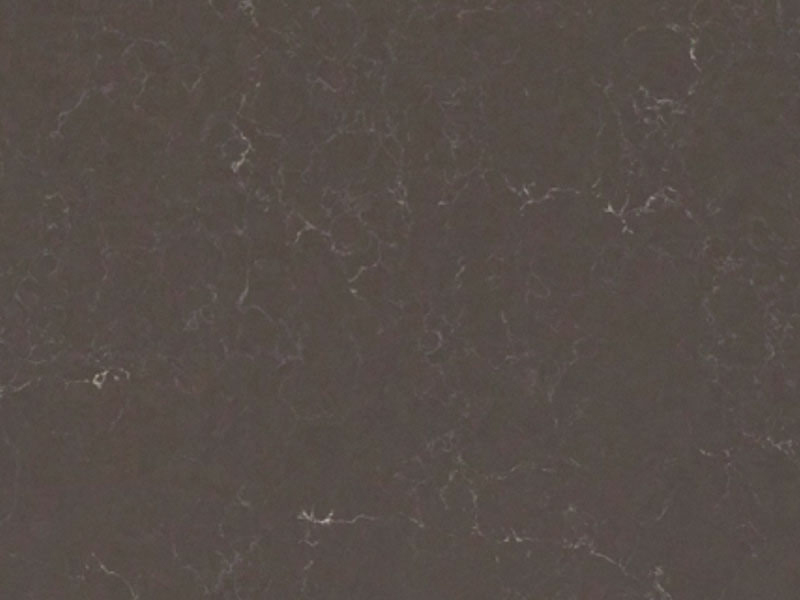

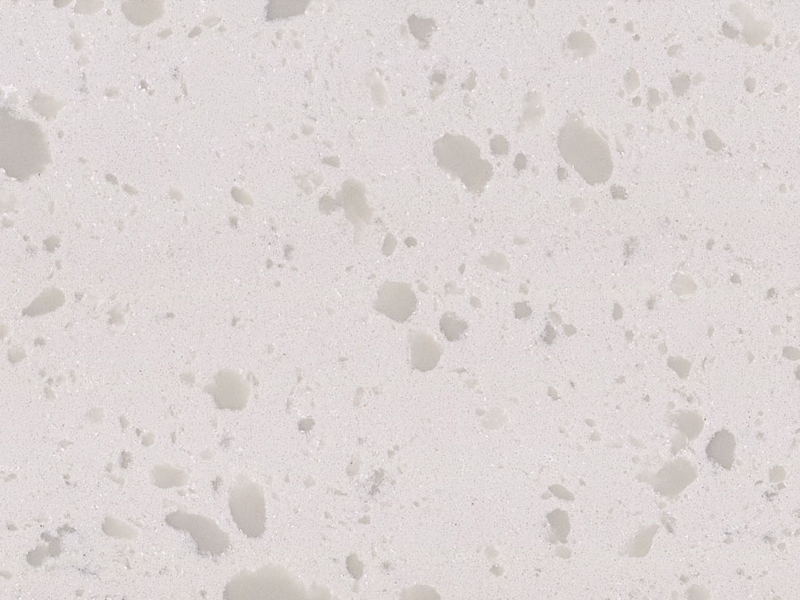

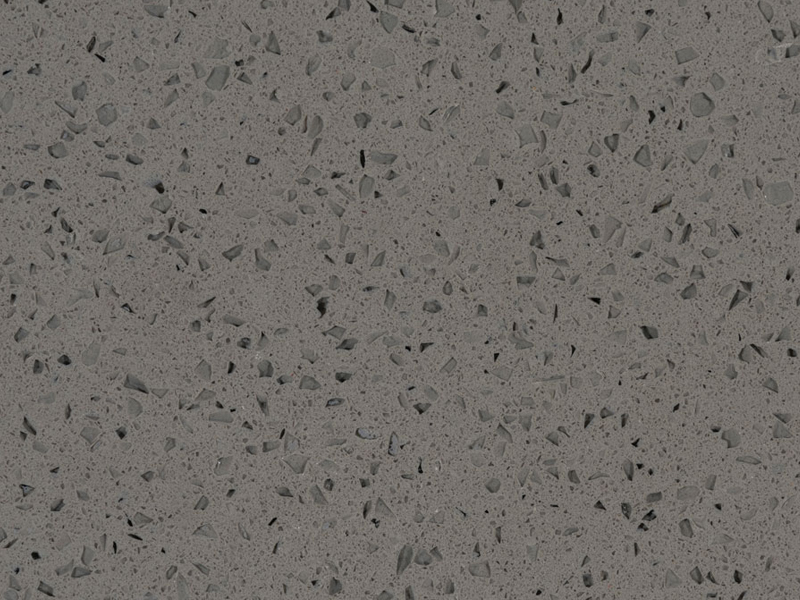

Quartz Slabs

We at Akron, supply premium quality slabs, which are made from natural quartz. Our manufacturer has a fully automatic pressing line with mould technology. This enables us to reduce manufacturing process defects. All slabs are then calibrated on both sides followed by polishing on a fully automatic machine using Italian abrasives. We provide even custom colours as per your requirement, which are formulated in state-of-the-art lab.

Quartz Cut to Size

We are exclusively focusing on the cut to size and project segment and prefabs. Unlike other plants which use rejects for making prefabs, which means multiple lots and variation in shade, we supply premium slabs exclusively for projects. This ensures consistency and quality. This also helps in faster turnaround time. We even provide custom colours and edges as per your requirement and the finished product is calibrated to perfection. Our suppliers are fully automatic with 4 axis bridge cutters, 5 axis CNC machines and 5 axis water jets, mitre saws and edge polishing machines apart from many other ancillary machines required to give you the perfect finished.

Areas of Application

- COFFEE TABLES

- BATHROOM VANITY TOPS

- CONFERENCE TABLES

- KITCHEN COUNTER TOPS

- LIVING ROOM CONSOLE TOPS

- RECEPTION TABLES

- STAIRCASE

- WALL CLADDING

- ISLAND

Can be done in all colours we carry as seen in our slab section and we can even make custom colours for large projects.

Edge profiles

Standard

Bevel, Demi-Bullnose, Double-Eased-Edge, Double-Pencil-Round, Double-Radius, Eased-Edge, Full-Bullnose, Half-Bullnose, Knife-Edge, Pencil-Round, Radius

Laminated

Doubled, Eased-Edge, Full-Bullnose, Half-Bullnose

Metered

Pencil-Round

Our Process

Drawings & Colour

Send us draft shop drawings, along with pictures of colour approved by builder/architect.

Quotation

We will submit quotation within 48 working hours of receipt of drawings & colour details.

Approval

You approve quotation sent by us as well as courier us a sample of colour approved by builder/architect for matching. In case final drawings are required from our end the same can be prepared and sent for signature.

Production

We produce slabs exclusively for the project, which will ensure premium material with minimal variation/shade issues.

Fabrication

Our team will prepare the cutting sheets, load them on the bridge saws and waterjet machines and ensure precise execution.

Quality Check & Packing

We check each piece for size, colour, thickness, surface finish before it is packed. Packing is done using Australian pinewood as per instructions received from the buyer. All pieces as well as boxes are labelled to ensure easy installation.